Çelik Yapı İmalat: Transforming the Construction Landscape

In today's rapidly evolving construction industry, çelik yapı imalat (steel structure manufacturing) stands at the forefront of innovation and efficiency. This method of construction emphasizes durability, cost-effectiveness, and design flexibility, making it an increasingly popular choice for both residential and commercial projects. This article delves into the various aspects of steel structure manufacturing, highlighting its benefits, applications, and the future of this essential industry.

Understanding Çelik Yapı İmalat

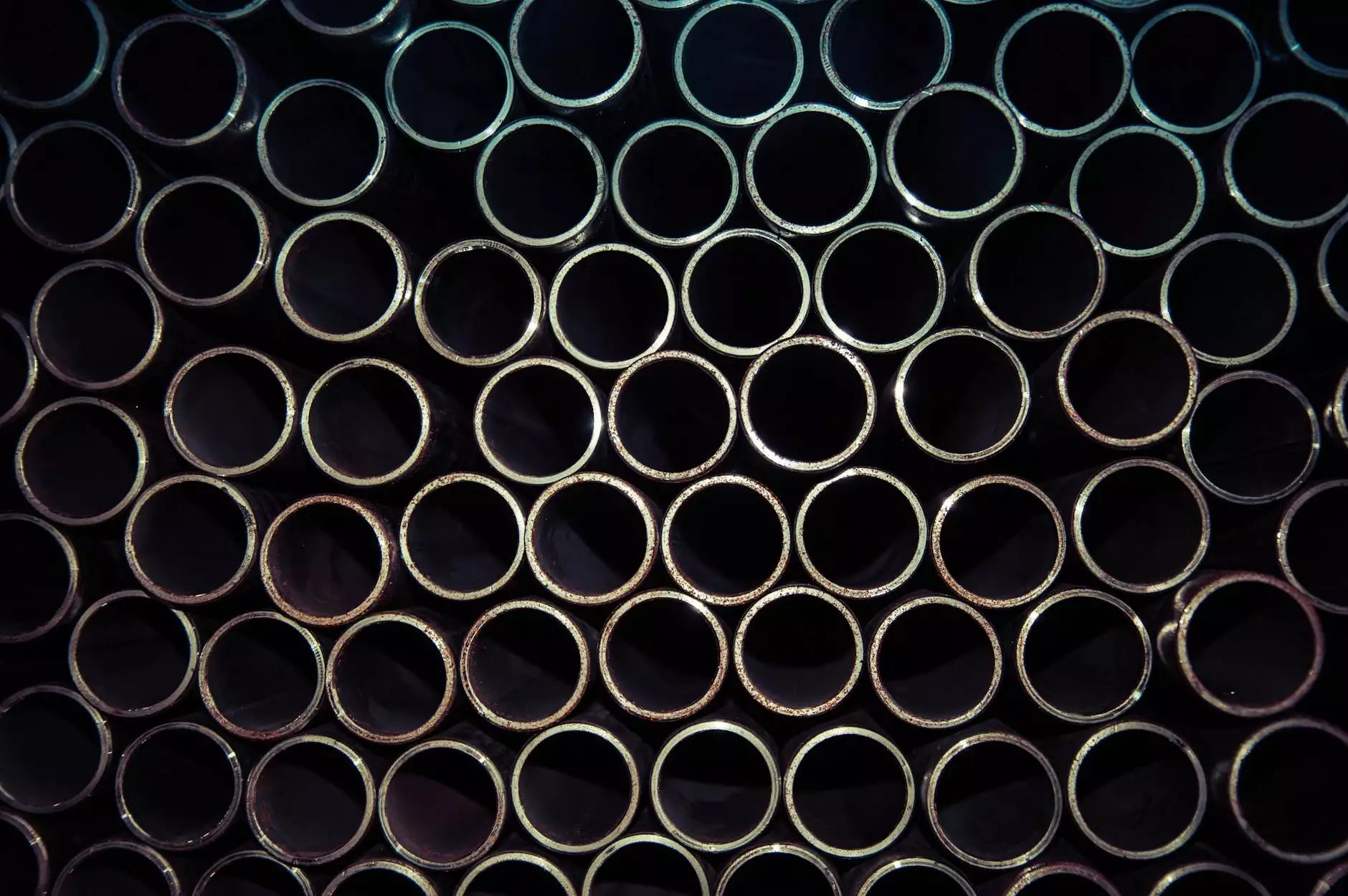

The term çelik yapı imalat refers to the intricate process of producing steel frameworks that form the backbone of many modern structures. Steel, known for its remarkable strength-to-weight ratio, is engineered to provide superior support and stability. The components produced through çelik yapı imalat are crucial in a variety of construction projects, ranging from simple residential buildings to complex industrial facilities.

The Key Components of Steel Structure Manufacturing

- Steel Beams: Structural elements that bear loads and provide support across the length of buildings and structures.

- Columns: Vertical supports that transfer load from the beams to the foundation, ensuring stability.

- Trusses: Frameworks that provide support while allowing for open spaces, commonly seen in roofs and bridges.

- Sheet Metal: Used for walls and roofing, offering protection against environmental elements while being lightweight.

The Advantages of Steel Structure Manufacturing

The adoption of çelik yapı imalat in construction comes with numerous advantages that contribute to its growing popularity:

1. Durability and Longevity

Steel structures are renowned for their durability. Unlike traditional building materials, steel is resistant to warping, cracking, and settling. Its robust nature ensures that buildings last longer with lesser maintenance costs, making it a wise investment for developers.

2. Cost-Effectiveness

Although the initial costs of steel might seem higher, the overall cost-effectiveness becomes apparent over time. The speed of construction, coupled with reduced labor costs, often results in lower total project expenses. Additionally, the durability of steel reduces the need for frequent repairs and replacements, further maximizing savings.

3. Design Flexibility

Steel's versatility allows architects and designers to experiment with various architectural styles. From tall skyscrapers to expansive warehouses, steel structures can be tailored to accommodate diverse design requirements. This flexibility not only leads to aesthetically pleasing structures but also enables functional adaptations as needs evolve.

4. Sustainability

In an age where sustainability is paramount, çelik yapı imalat shines as a greener alternative. Steel is 100% recyclable and can be reused without losing its quality. By choosing steel, developers contribute to reducing waste, supporting eco-friendly construction practices, and promoting sustainable urban development.

Applications of Steel Structures in Modern Construction

The versatility of çelik yapı imalat manifests in a wide range of applications, including:

- Commercial Buildings: High-rise office buildings and retail spaces utilize steel for aesthetic appeal and structural integrity.

- Industrial Facilities: Factories and warehouses benefit from steel’s strength and adaptability to heavy loads.

- Residential Construction: Modern homes increasingly incorporate steel for unique designs and open floor plans.

- Bridges and Infrastructure: Steel’s high tensile strength makes it ideal for constructing bridges and overpasses, ensuring safety and longevity.

Innovations in Steel Structure Manufacturing

The field of çelik yapı imalat is witnessing remarkable innovations aimed at improving efficiencies and enhancing overall construction practices:

1. Advanced Fabrication Techniques

The advent of Computer Numerical Control (CNC) machinery has revolutionized the manufacturing process. These machines allow for precision cutting and shaping of steel components, resulting in more accurate and faster production times. This innovation not only improves quality but also reduces waste significantly.

2. Prefabrication and Modular Construction

Prefabrication is transforming how steel structures are produced. By manufacturing components off-site and assembling them on location, projects can be completed in less time with significantly reduced labor costs. This method ensures higher quality control and less disruption to the construction site.

3. Smart Steel Technologies

The integration of smart technologies into steel structures enhances performance and monitoring. Sensors can be embedded into steel components to provide real-time data about structural integrity, which aids in proactive maintenance and longevity.

Challenges in Steel Structure Manufacturing

While çelik yapı imalat offers numerous benefits, it is not without its challenges. Understanding these obstacles is crucial for stakeholders:

1. Fluctuating Steel Prices

The construction industry frequently faces price volatility in raw materials, particularly steel. This unpredictability can affect project budgets and timelines, requiring effective cost management strategies.

2. Skilled Labor Shortages

As technology advances, the demand for skilled labor in the steel manufacturing sector continues to rise. Training programs and initiatives are essential to bridge this gap and ensure sustainability in workforce capabilities.

3. Environmental Considerations

Despite its recyclable nature, the steel manufacturing process can have significant environmental impacts, including energy consumption and emissions. Adopting greener manufacturing practices is vital for the industry's sustainable future.

Conclusion: The Future of Çelik Yapı İmalat

The future of çelik yapı imalat is bright, informed by a commitment to innovation, sustainability, and efficiency. As the construction industry continues to evolve, metal structures will play an increasingly vital role in building our environments. Embracing advanced technologies and practices will ensure that steel remains at the forefront of modern construction, driving forward the need for durable, affordable, and aesthetically pleasing structures.

For businesses and developers looking to invest in steel structure manufacturing, understanding these elements is crucial for making informed decisions that benefit not just their projects but also the broader community and environment.

For more information about çelik yapı imalat and the latest trends in steel structure manufacturing, visit izmircelikkonstruksiyon.com.