Prototyping in China: The Future of Business Innovation

The world of business is rapidly evolving, and prototyping in China stands at the forefront of this transformation. With an unprecedented ability to combine innovation and efficiency, China has become a global leader in manufacturing and product development. In this article, we will explore the myriad benefits of prototyping in China, the cutting-edge technologies employed, and how businesses can leverage these advantages for success.

1. Understanding the Prototyping Landscape in China

Prototyping is the process of creating a preliminary model of a product to test and evaluate its design, functionality, and feasibility. In China, this process is not just common; it is refined to an art form. The prototyping industry in China is characterized by:

- Advanced Technology

- Skilled Labor Force

- Cost Efficiency

- Speed of Production

2. The Advantages of Prototyping in China

Choosing prototyping in China offers numerous advantages for businesses looking to bring new products to market swiftly and cost-effectively. Some of the most notable benefits include:

2.1 Cost Efficiency

One of the most compelling reasons to consider prototyping in China is the significant cost savings. The overall expense for manufacturing prototypes is considerably lower than in many Western countries. This cost-efficiency is due to several factors:

- Lower labor costs

- Economies of scale in materials purchasing

- Reduced overheads in manufacturing facilities

2.2 Access to High-Quality Manufacturing

Contrary to popular belief, not all production in China is of low quality. In fact, many Chinese manufacturers maintain strict quality control standards and adhere to international certifications. By collaborating with established factories known for their quality output, businesses can ensure that their prototypes meet the highest standards. This quality assurance fosters trust and enhances brand reputation in the long run.

2.3 Rapid Turnaround Times

Time-to-market is crucial in today's fast-paced business environment. China’s manufacturing sector boasts an ability to produce prototypes quickly, such that businesses can move from concept to creation in a matter of weeks. This speed allows companies to:

- Gather feedback through trials

- Make iterative improvements

- Accelerate the product launch process

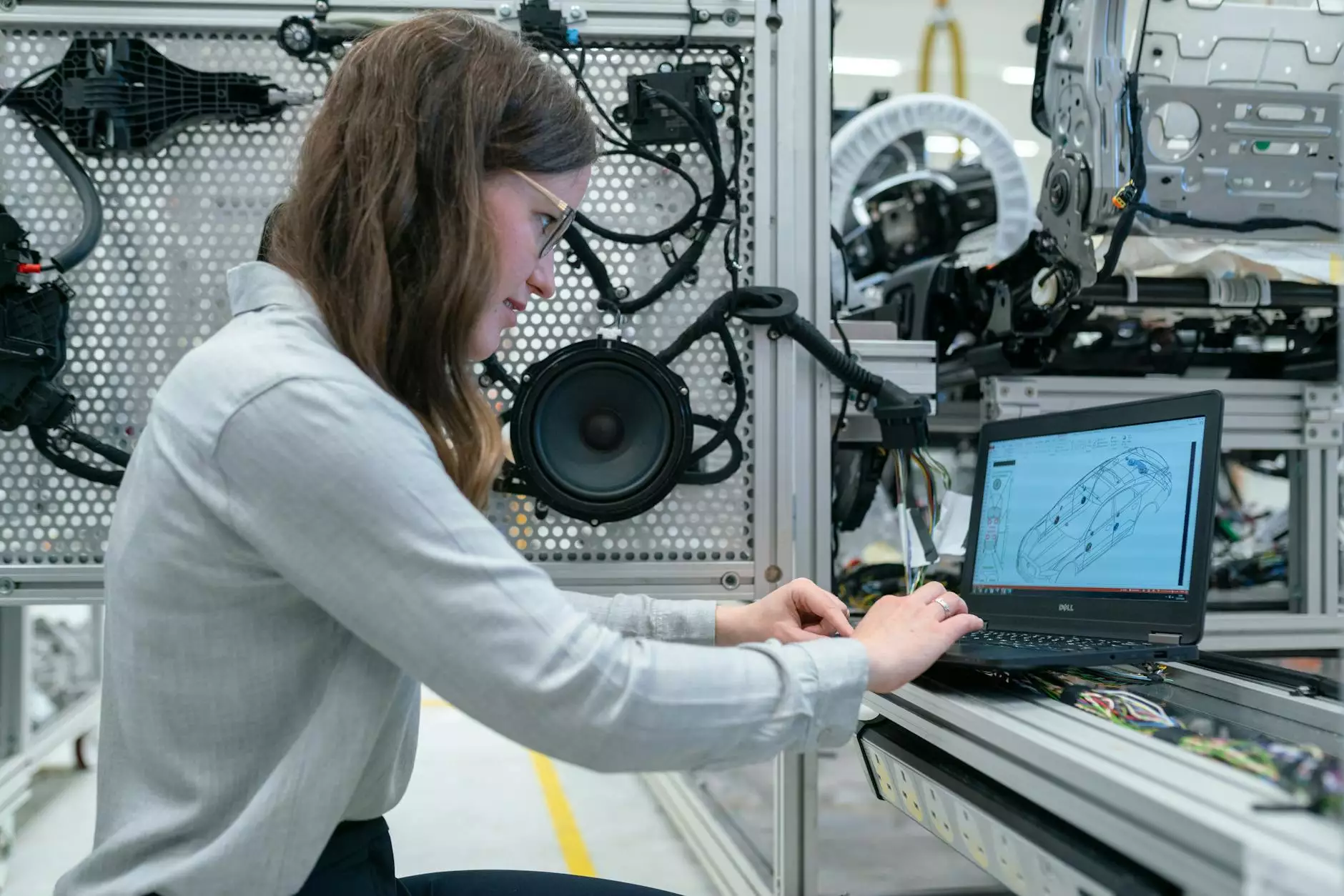

3. Technologies Enhancing Prototyping in China

The prototyping industry in China leverages advanced technologies that facilitate rapid development and high-quality output. Some of these technologies include:

3.1 3D Printing

3D printing technology has transformed the prototyping landscape. Chinese manufacturers have embraced 3D printing to create intricate designs and components with great precision. This technology allows for:

- Faster prototype iteration

- Complex geometries that traditional methods cannot achieve

- Reductions in waste and costs associated with traditional manufacturing

3.2 CNC Machining

CNC (Computer Numerical Control) machining is another key technology utilized in the prototyping process. This method allows for:

- High precision machining of metal and plastic components

- Scalability from prototype to mass production

- Consistency in quality and dimensional accuracy

3.3 Injection Molding

For businesses looking to prototype plastic components, injection molding is a crucial process. By producing molds quickly, manufacturers can create prototypes that closely resemble final products, allowing for comprehensive testing and feedback.

4. Choosing the Right Partner for Prototyping in China

When considering prototyping in China, selecting the right manufacturing partner is essential for the success of your project. Here are key factors to consider:

4.1 Experience and Expertise

A partner with a proven track record in your industry will understand the technical requirements and challenges specific to your product. Look for companies that have a history of successful prototypes and customer satisfaction.

4.2 Communication and Transparency

Effective communication is vital to ensure that your vision is accurately conveyed. Choose a partner that values transparency and keeps you informed throughout the prototyping process.

4.3 Quality Control Processes

Investigate the quality control measures that your potential partner has in place. A robust quality assurance system is indicative of a commitment to delivering high-quality prototypes.

5. The Future of Prototyping in China

The future of prototyping in China is bright, characterized by continuous advancements in technology and manufacturing processes. As sustainability becomes a pressing concern globally, Chinese manufacturers are also striving to adopt eco-friendly practices. Expect to see:

- Increased use of recycled materials in prototypes

- Innovative manufacturing techniques that reduce waste

- More sustainable energy sources being utilized in production

6. Conclusion

In conclusion, prototyping in China represents an exciting opportunity for businesses aiming to innovate and compete in the global market. With significant cost savings, rapid turnaround times, and access to superior manufacturing technologies, China is poised to remain a leader in the prototyping sector. By carefully selecting the right partners and strategies, businesses can harness the potential of Chinese manufacturing to bring their concepts to reality efficiently and effectively.

As the demand for faster, more efficient product development continues to grow, companies that leverage the strengths of prototyping in China will undoubtedly gain a competitive edge in their respective markets. Embrace the future of business innovation and discover the possibilities that await in the realm of prototyping.

prototyping china